The evolution of digital apparel printing at Threadless

Threadless has been printing T-Shirt designs submitted by our artist community since November of 2000. From 2000-2011, we relied 100% on screen printing to produce our products. We started researching more about digital printing in 2007 as the technology began to show a lot of promise. It wasn’t until 2011 that we felt the quality of direct-to-garment (DTG) printing was ready for primetime. In 2011, we began experimenting with offering some of our designs printed “on demand” through DTG printing. This allowed us to offer designs for sale without inventory sitting on a shelf, and without running out of stock of something our customers wanted to buy. Instead, when an item was purchased, it was made-to-order and then shipped to the customer. By 2015 we had shifted 100% of our production from screen printing to DTG printing. In doing so, we’ve also been able to launch a new platform called Artist Shops that allows anyone to set up their own online store where we handle all the operations like manufacturing, fulfillment, and customer service.

Many industries have recently evolved from analog to digital. Using Music & Photography as examples, you can point to very specific changes in the technology that improved the quality to an inflection point. The compression algorithms changed for music files, the bit rates got better, there were more megapixels in the photo file, higher ISO settings became available, autofocus got better and faster, etc. You knew that when you download a music file, the quality depends on the file format and settings. When you buy a new phone, you know the camera quality is better because it has better hardware and software in it.

There have been MAJOR improvements in digital apparel printing over the last 10+ years. However, the improvements are much more difficult to pinpoint as a consumer. Below, we’ll walk through some of the key places these improvements are found.

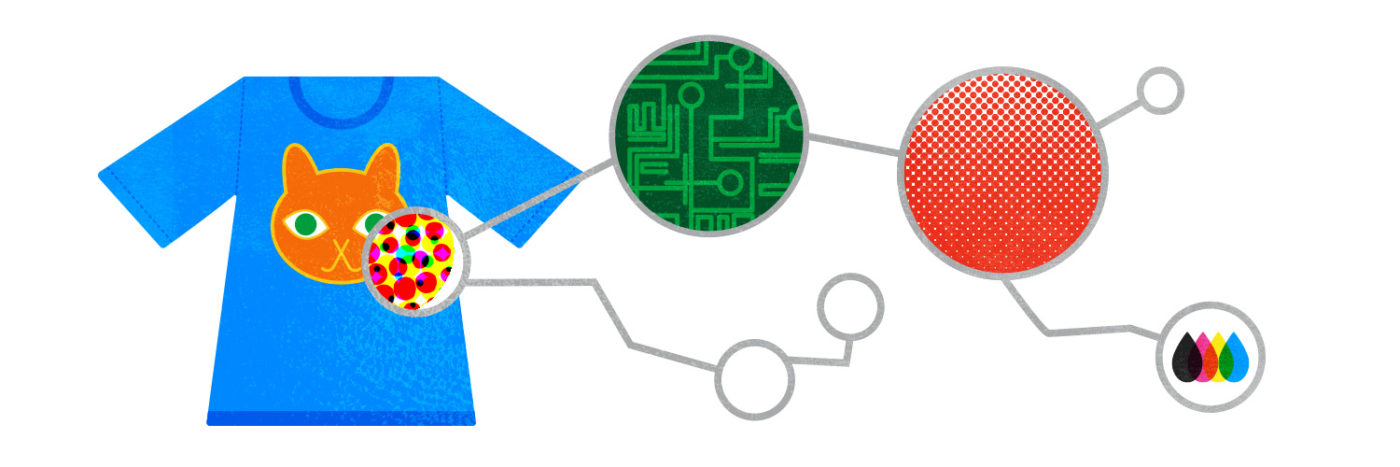

Printer Technology

Digital apparel printing is very similar to inkjet printing on paper except for two major differences. First, the print is on fabric rather than paper. Second, when printing on darker fabrics, a white underbase needs to be printed first, and then the graphic is printed on top of that. Due to these differences, specialized printing technology has been developed specifically for digital printing of apparel. This printing equipment is made and supported by a number of different companies, some relatively new and some that have been around a long time.

The leading manufacturers of DTG printers are Kornit, Brother, and Epson. There are many others as well like Aeoon, AnaJet, and DTG Digital. A new trend in DTG printing technology leverages a traditional screen print carousel setup with stations for various steps like pretreat, heat press, underbase, and the actual print. Some screen printing machine manufacturers have developed DTG technology, like the M&R Digital Squeegee. HP is also rumored to be developing a revolutionary new DTG printer.

Many of these manufacturers are on their 10th or more version of their machines and have made countless improvements with each new model release. There are a huge range of factors being improved on such as: the DPI (dots per inch) that the printer can print, the pretreat process used, the underbase technique for dark garments, the inks and color ranges possible, the printing speed, the up-front and ongoing costs, the print head maintenance procedures, the feel of the print, the maximum graphic print size, neck label printing, and the software which I’ll go into more detail on below. All of these and other factors are being constantly improved upon each year.

In addition to the printer itself, a conveyor dryer is also required for DTG printing in order to cure the ink. Based on the garment and ink coverage, many prints require different temperatures and speeds in which they are cured in order to ensure a durable print that stands up over time. Also, many DTG printers do not pretreat the garment in the printer (some do) which means that more machinery is required for applying the pretreat solution, which is an art in itself. Each garment type, fabric, and color often needs a different amount of pretreat, and it’s also typically best to ensure the pretreat is only applied where the garment is printed, which varies based on the graphic. All of these areas show improvement each year, with smart dryers and pretreat applicators that can be automatically adjusted for each garment they encounter.

Software

Another crucial factor in getting a quality DTG print is the software used throughout the process. First, you have the print file itself. There are many best practices in creating files optimized for a DTG print. We outline our suggestions here.

The most important piece of software is the raster image processor (RIP). A RIP breaks apart the graphic file into a set of instructions for the printer to use when printing the file. Many suppliers develop their own RIPs rather than using the out-of-the-box solutions from the printer. In order to produce the best results, we’ve found that it’s best to have unique RIPs specific to the garment the graphic is to be printed on. Depending on the background garment color, there may be colors that could be removed from the print file to produce a better result. Sometimes colors need to be more highly saturated for darker garments and/or for how the ink interacts with the underbase coverage (the underbase is white ink printed underneath the graphic on dark garments).

Sizing the art file for the garment that is to be printed on can be a surprisingly complicated process. How does the graphic scale from a Newborn Onesie up to a 5XL Men’s Tee? Each garment size and style has a print palette sized for that garment and the file needs to be sized appropriately for the palette. We have custom software we’ve built to make these decisions.

Another important software element controls the Quality Control processes at the supplier. We require that our suppliers compare the finished product with an on-screen representation of the print file and the product mockup image that the customer ordered from to ensure that our quality standards have been met before shipping.

Software improvements are happening faster than any other area I’ve outlined in this post. There are changes happening rapidly, often on a weekly or monthly basis. These updates are incrementally improving the overall quality of DTG printing.

Garments

Every garment prints differently depending on it’s fabric, size, color, etc. Sometimes even the exact same garment can print differently when produced in a different dye lot or even re-dyed from another color (it’s common for a color that isn’t selling to be re-dyed black rather than to throw away that inventory). Given that DTG printing literally prints directly to the garment, it’s important that the garment can be pre-treated properly to receive the print. Each printer has its own pretreat process, but the general idea is to press the fabric to create a flat and smooth printing surface. On Threadless & Artist Shops, our new “Extra Soft Tee” and “Premium Tee” (in addition to being super soft, comfortable garments) are both optimized specifically for DTG printing.

Each garment – type, size, color, fabric – must go through a research & development process before it can be made available in order to optimize each step of the DTG print process for that garment. Some garments require more or less pretreat solution, some need to cure at different temperature and speeds, some may require a change to the RIP software, the palette it will be printed on needs to be defined, etc. Fine tuning each of these bits leads to better and better quality prints over time.

Suppliers

Not all print shops are created equal! Even if a supplier uses the exact same printing technology as another supplier, their print quality and consistency can be completely different. This can be due to volume amounts, employee expertise with the equipment, customizations made to the equipment, or differences in process. Printing equipment is often customized by suppliers the day it arrives. Some suppliers like to modify their printers to do things like recycle inks or use their own software and RIPs. When a supplier receives ongoing, steady volume from their clients, they are typically able to maintain a more consistent level of quality because they don’t need to bring in new, untrained labor.

The printing operator at a supplier can also have a huge impact on print quality. Many printing systems have complex settings in their software that can be adjusted for every print. A highly skilled operator can get a better print out of a machine than an inexperienced operator. It’s also important for suppliers to have a culture of quality. What may pass a quality control step by one supplier’s employee may not pass at another. These are ongoing challenges that we’ve seen improvements on year-over-year.

Quality Control Processes

Given how many variables go into printing a single garment using DTG printing, the biggest challenge is maintaining consistency from print to print. When a screen printing job of 1,000+ units of the same design is produced, you can spot check a few of them and feel pretty good that the whole batch is OK. But with DTG printing, each garment and design coming off the line is usually unique. It’s important to look at and check every single one of them for quality, multiple times throughout the production process. This can make the spoilage rate higher and requires more labor which makes things much more costly. But we’d much rather be the ones to find an issue with a print than have the customer discover the issue!

Our quality control processes have changed greatly over the years and have lead to a more reliable result in print quality. That said, we’ve also taken a new approach when it comes to Returns & Exchanges. When we first launched DTG printing, since every item was made-to-order, we did not accept returns. Now, we have a “100% Happiness Guarantee” – if you receive a print from us that is not up to par we will replace it for free, and you don’t even have to send us back the misprint. We record customer feedback when a print goes wrong and determine the source of the issue. We then work with our print team to make changes that help ensure the issue will not happen again.

Costs

A common misconception is that DTG printing is cheaper than screen printing. That’s true if you order just 1 unit because of all of the setup costs involved with screen printing. However, once you start ordering in larger quantities, screen printing is still MUCH more cost effective on an order of magnitudes. Also, the up front capital expense of DTG printing equipment is much higher than that of screen printing, as are the operating costs like ink, maintenance, and labor. That said, there are no risks in unsold inventory associated with DTG printing since each item is made-to-order. However, DTG costs are getting lower and lower each year and, as the technology continues to advance, could eventually become an economical alternative to screen printing even for larger quantities.

What’s the future like for DTG printing?

I’m no fortune teller, but I can confidently say that digital printing is here to stay and will continue to improve every year. It will be interesting to see how far DTG printing disrupts screen printing. If the costs continue to decrease, it could quickly become a more viable option for smaller quantity orders that currently make more sense to screen print. From a quality perspective, we will continue to see new printing technology and software released frequently with marked improvements in quality. There will be more and more competition in the marketplace among printing equipment manufacturers, DTG suppliers, and front-end consumer brands leveraging the technology.

One thing’s for sure, DTG print quality has already reached an incredibly impressive milestone and it continues to improve every year.