We live in a digital world. From the music industry to the photo industry, the creative world has been not-so-gradually making the move to digital for years now, and the retail industry is no exception. But just as the photo and music industries had to learn new ways of putting their creations out there, with digital printing comes new ways to prepare your designs to get the best possible final product. We’ve put together a guide that breaks down everything you need to know to maximize the vibrant look of your designs and to get your design ready for our on-demand printing system. Find out how to optimize your design files and how to ensure high quality DTG and sublimation prints! (And if you still need help on how to set up those files in the first place, check out this guide.)

. . .

First: What is On-Demand Printing?

On Threadless and in Artist Shops, we use on-demand printing: a method where a digital printer is used to print a design directly onto a garment using inkjet technology with direct-to-garment (DTG) or sublimation printing (where all-over prints come from). Think of a computer printer that uses a tee or mug instead of paper. With this process, inks are absorbed by the fibers in the garment. Therefore, knowing how certain materials affect certain colors in a print can help you ensure high quality DTG and sublimation prints.

Why On-Demand Printing?

The tl;dr version: Direct-to-garment (DTG) digital printing has become on par quality-wise with many traditional screen printing methods. Artist Shops uses DTG printing because it’s less limiting to you – the artist – and allows us to offer you tons of awesome products to print on.

The details: While screen printing is a great method, the process behind it would limit product turnaround, would slow down how quickly you could keep a product in stock and how quickly your customers would receive their orders, and is more time- and money-consuming than on-demand. When you screen print, an individual screen needs to be made for each color in your design. So while screen printing has tons of color possibilities, this can be limiting in terms of product turnaround.

DTG allows our artists to take more design risks without inventory that would remain unsold and means that you’ll never run out of stock on any of your designs. So we can invest more in artists and less in inventory that may not allow for taking those design risks.

How Colors Print on DTG

One way to get the most out of DTG printing is to know how to avoid possible faded color situations. DTG provides tons of versatility in terms of color options and product options, but because you’re printing directly onto a garment, certain garment types may affect how those colors show up. Here’s a quick guide to how certain colors and shades appear on various types and colors of fabric!

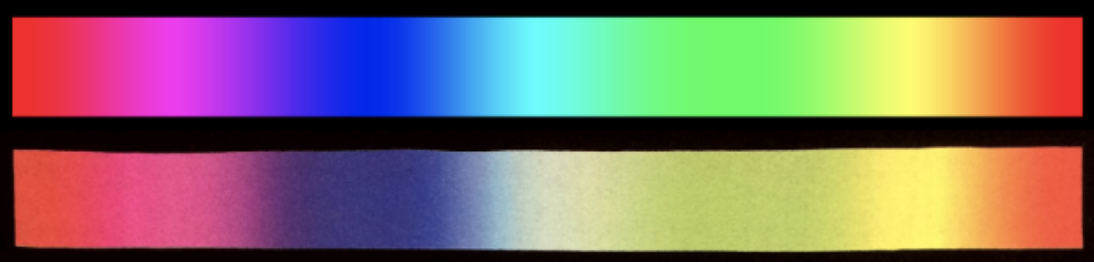

The DTG Color Spectrum

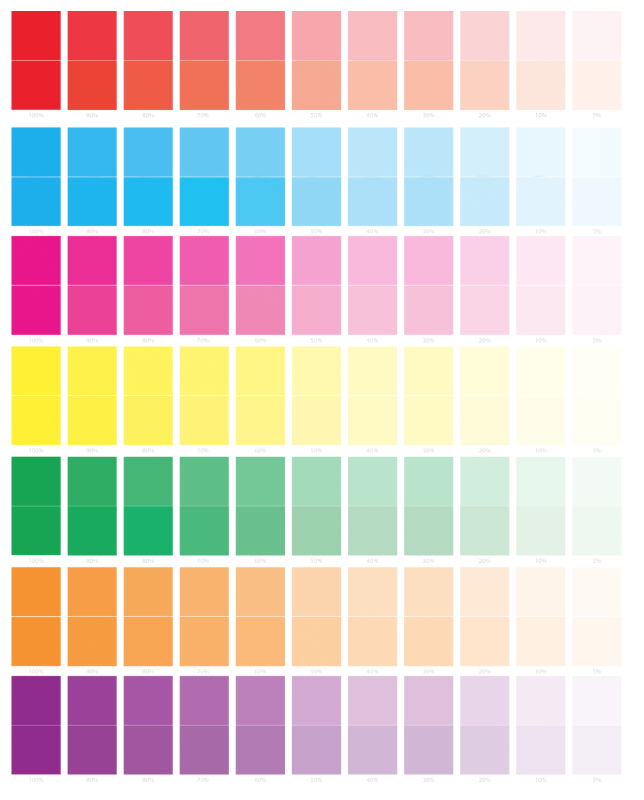

Some colors show up better on certain DTG garments than others. Above is a full-color spectrum (top bar) vs that same spectrum (bottom bar) printed on DTG. As you can see, the hardest hues to hit are the bright reds, cyans, and greens. Let’s use this color swatch template as our reference to explore quick spectrums of these colors (there’s a version you can pull into Photoshop for easier visuals in this article):

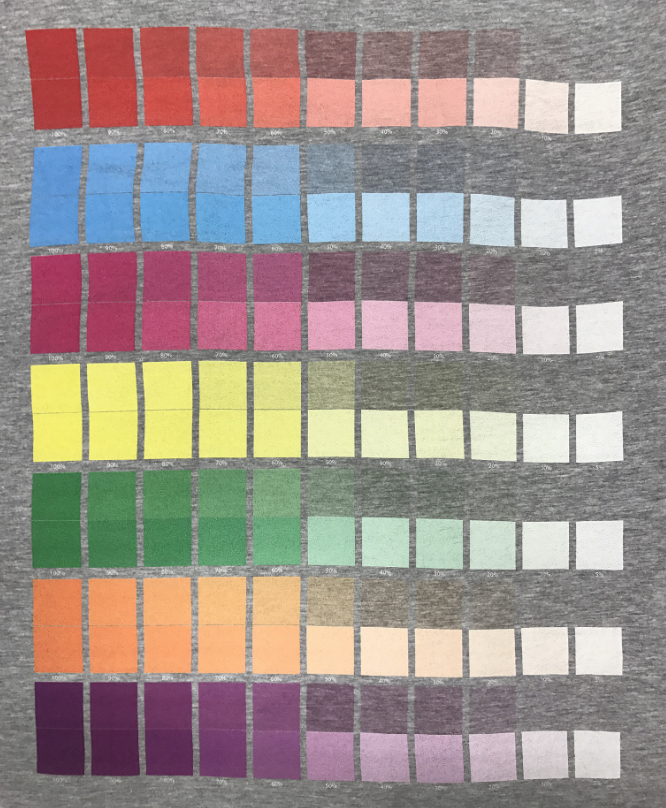

On this template, the top row of colors starts with a solid color, and each swatch after it is a % transparency of that color. On the bottom row is if the same color had a white background behind it and used the eyedropper in photoshop to get the solid hex value. Here are some printed versions of this template:

On a black garment:

On a heather gray garment:

And on a white garment:

Note that on white, all colors fade naturally because prints done on white shirts do not use an under-base. Designs on other colors will use a white under-base that will make your transparencies fade out to a lighter color as opposed to a darker one.

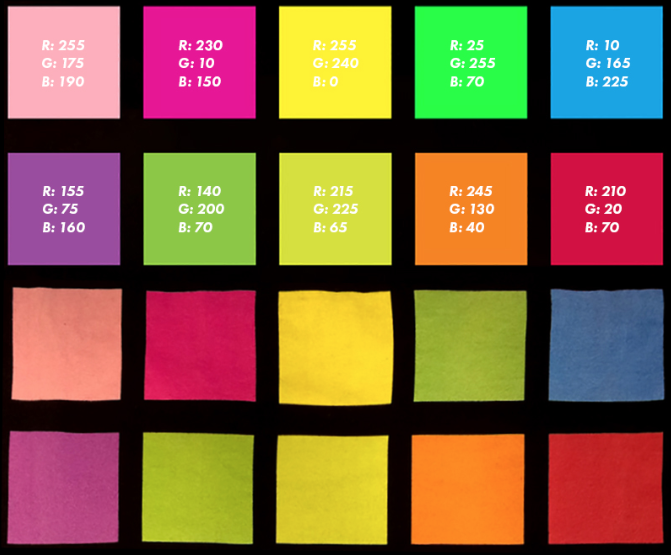

Since DTG files are printing in RGB, it’s difficult to achieve super bright and neon CMYK colors. Here are our RGB suggestions to achieve those neon and pastel colors:

How Black Inks Print on DTG

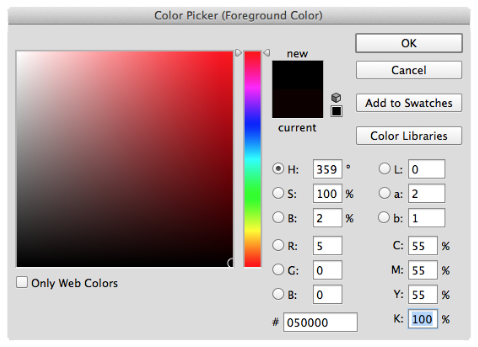

“True Black”

Although true black is usually #000000, achieving this on our DTG printers is a bit different. The way to get a nice dark black – especially on lighter garments – is with the CMYK values 55,55,55,100, respectively.

White Transparencies on DTG

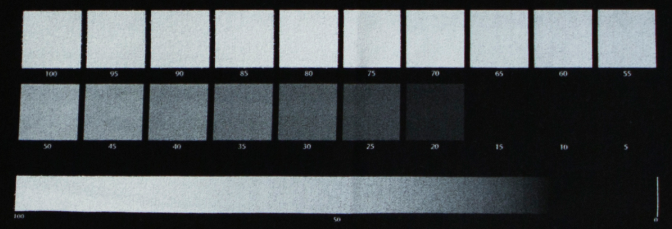

Here is a spectrum of different opacities of white ink so you can see how it will print. We recommend staying above 30% opacity. As you can see, any transparencies lower than 30% are either super faint or don’t show up at all – keep that in mind when designing!

On-Demand vs. Original Design File

Let’s look at what a design file looks like while it’s on the computer vs how it looks once it’s actually printed. We’re going to use Lim Heng Swee’s “You Are My Universe” as an example.

Pros vs Cons of DTG vs Screen Printing

Here are a few pros and cons of DTG vs screen printing.

-

- Saturation is higher in screen printing. While on-demand can achieve nice and bright colors, there are certain hues (i.e reds) that will print a little bit more toned down.

- With screen printing, you need to have a new screen for every color in your design, so the screen printing process can take a lot longer than on-demand, which slows down the turnaround time that customers would get an order from your shop.

- Halftones with higher frequencies can be achieved nicely on screen print but can get lost with on-demand because of their small size. With on-demand, we’ve found that frequencies less than 25LPI prevent the largest loss of details (see image below).

- With screen printing, you run the risk of running out of certain sizes or styles of a design and having to wait until the items are remade and restocked. Because on-demand is made as you need it with a faster process, you don’t run the risk of running out of stock.

Inks

What types of inks do we use?

All of the inks used in our on-demand printing are water-based. They do not contain PVC, phthalates, or AZO dyes.

Why does my shirt smell a little funny?

That odor you may smell on your new tee is a by-product of the custom printing method used to print the design. This is just temporary! Now that your tee is out of the confined space of the shipping bag, the printing smell will go away after a few days and a wash cycle.

Try it Out!

On-demand is a great way of getting a quality product out to customers quickly; that’s why we love it! Using the above suggestions, you can make sure that your design is ready for the on-demand process and will look amazing. Go try it for yourself! And if you have any tips on how to ensure high quality DTG and sublimation prints, leave it in the comments!

. . .

Illustrations by Katie Lukes.

Want to start an online business? Try Artist Shops for free!